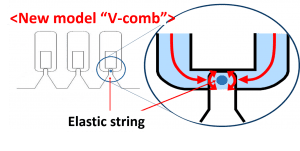

- Comparison of conventional and new shim-shaped products

We’ve enhanced our elastic string round coating technology by dispensing melt from 2 holes on both sides of the nozzle.

- Dispense adhesive from the 2 holes on both sides of the nozzle to apply round coating on elastic strings.

- Increase the ability to coat all-round surface, results in higher adhesive performance.

- Apply high adhesive strength and prevent coming-off the strings.

- Support high-speed production lines up to 500 m/min.

- Eliminate negative factors such as clogging of the airhole or scattering hot melt without air support.

- Also have the function which detects a knot and skip it automatically, Continue application and reduces loss.

*The width of module is same as the width of cavity. Coating balance has improved(depending on coating pattern)

- We’ve succeeded in enhancing our elastic string round-coating technology.

New model V-comb applicator compared to our old model.

<Our old model>

<V-comb head>

Coating amount of Hot melt 0.04g/m

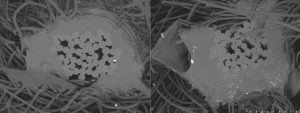

With V-comb’s round surface coating…

・Thread don’t come off.

・When pasting materials together, it is no longer loose and a smooth texture can be applied to the elastic parts.

■ Enhanced Adhesive strength

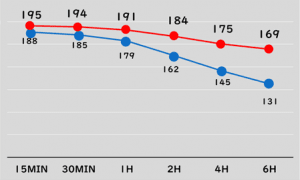

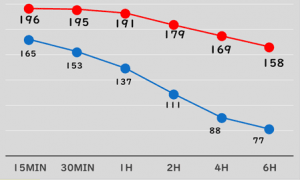

A comparison of the hot melt material consumption and the adhesive strength of the elastic strings used by the current product and the V-comb.

Horizonal axis :The amount of time elastic string material placed in the thermostatic oven at a constant temperature of 40℃.

Vertical axis :Displays the length 200 mm of the elastic string material

Fig.1

Fig1.Verify condition

String thickness :780dtex

GSM for V-comb :0.03 g/m

GSM for old model :0.04g/m

Drafting :3.5times

Fig.2

Fig2.Verify condition

String thickness :780dtex

GSM for V-comb :0.02 g/m

GSM for old model :0.04g/m

Drafting :3.5times

Specification

Slit Width : 0.2 ~0.5 mm

Production Speed Capability : 500 m/min

Operation Temperature : Normal temperature~200℃

Gun Module Air Pressure : 0.4MPa

Minimum Pitch : 3 mm

“V-comb” is the latest comb nozzle from SUNTOOL.

We have been providing our coating technology for Japanese hygienic product manufacturers for many years.

Above all else, our comb applicator coating technology which is applied on elastic parts for diapers, traning pants and adult diapers

has been on high demand by the clients.

While conversation with our clients, we heard about the issue of the “coming off the strings” or “loosing elastic parts”.

V-comb was originally developed in order to settle those clients’ issues.

This nozzle is available to support the continuous and intermittent pattern and the high-speed production lines up to 500 meter per

minute with our precise coating technology in according with the client’s request .

Our new model is able to dispense adhesive from the 2 holes on both sides of the nozzle to apply round coating on elastic strings.

By not using air, air circulation becomes simple and air clogging is eliminated which result in little or no effort on the customer’s

part while performing maintenance.

While focusing on all-round coating, a smooth texture can be applied to the elastic parts, keeping the adhesive amount to a minimum.