Spiral spray for laminating composite products

What’s spiral spray?

A state where spiral spray is applied

What’s spiral spray application?

A spraying method to apply adhesive to an object by discharging viscous liquid into a revolving air stream from a nozzle and forming fiber in spirals.

Wide application

Spiral spray is a stable non-contact application method for thin and wide application to laminate products.

The spiral can be formed at up to 60,000 rounds/min with the width of about φ15–20 mm.

The application method that follows the line speed realizes a beautiful spiral pattern with less overspray, whether the speed is high or low.

-

-

- Soft finish

- Cost effective

- Breathable

- Environmental/recycling measures

- Soft finish

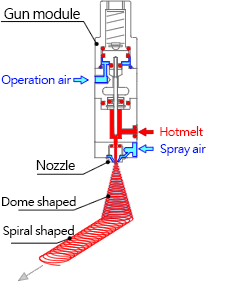

Working principle of spiral spray

Melted and pumped HMA is delivered to the gun module. The needle in the gun is raised by the operation air to deliver HMA in the gun to the nozzle and discharge it. The discharged HMA is extended in spirals by the air which is controlled to rotate to form fibers and reach the adherent.

The nozzle is the key.

SUNTOOL’s unique spiral nozzle uses secondary air.

What’s secondary air?

Air holes are added around the outer perimeter of the spiral nozzle to support the spiral air and block the accompanying air.

Problems of conventional nozzles

Conventional nozzles (without secondary air)

-

-

- Paper dust and HMA are deposited at the tip of the nozzles.

- HMA drips onto the base material subject to application.

- Irregular pattern results in poor application.

- Frequent suspension of production line due to nozzle clogging.

-

SUNTOOL’s solution

Nozzle with secondary air

Patented product

-

-

- Stable patterns can be created with the help of the guide air.

- Clean air protects the tip of the nozzle, thus minimizing maintenance due to adhesion of foreign objects.

- Spiral application of highly viscous HMA is possible (not possible with conventional nozzles).

-

Non-contact application

-

-

- Fibrous spiral patterns

- Low-pressure spray

- No overspray/breathable

- Application is possible at any specified angle.

- Fibrous spiral patterns

-

-